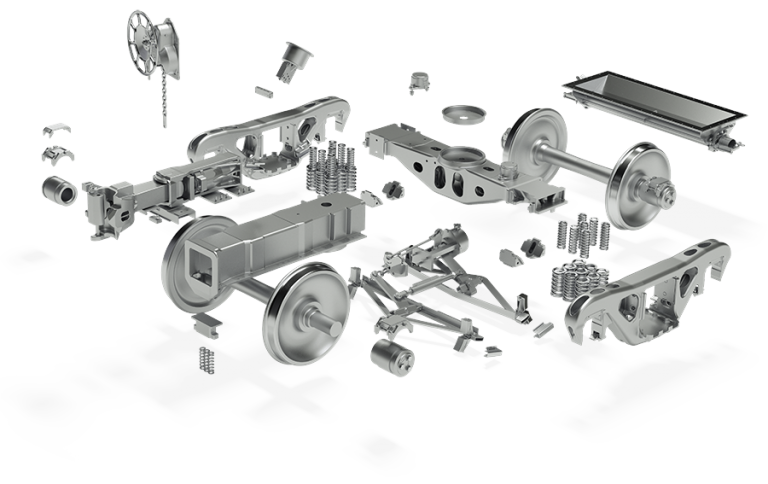

We deliver comprehensive system solutions built on the “Core Component Interaction” of castings, bearings, axles, wheels, and brakes. This integrated approach allows customers to select the optimal railcar design and corresponding Engineered System Solution. Our structured processes ensure a seamless, coordinated experience backed by expert guidance and support.

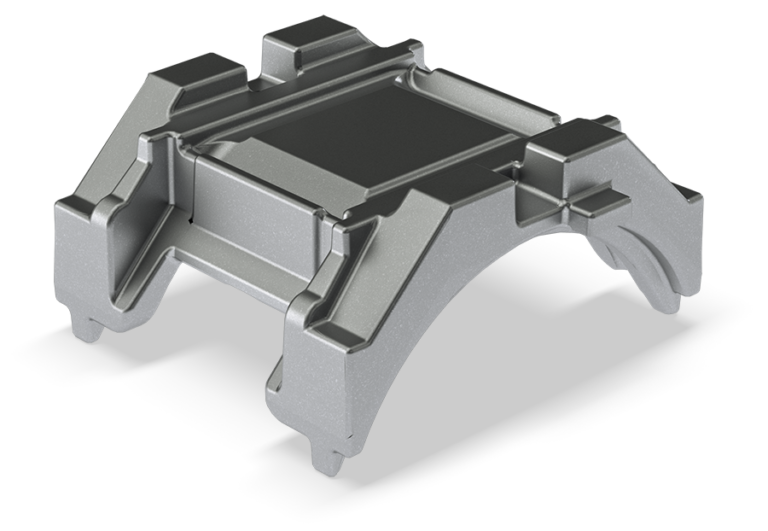

The Adaptor Plus Steering Pad System features an elastomer pedestal pad-liner-bearing adapter design that enhances axle-to-rail wheelset alignment. Unlike conventional all-iron adapters, this system allows controlled wheelset motion, reducing curve forces. This leads to a 50% increase in rail life for curves over 2 degrees, a 25% boost in wheel-set life, a 6%-8% decrease in fuel consumption, and a 35% extension in truck rebuild intervals.

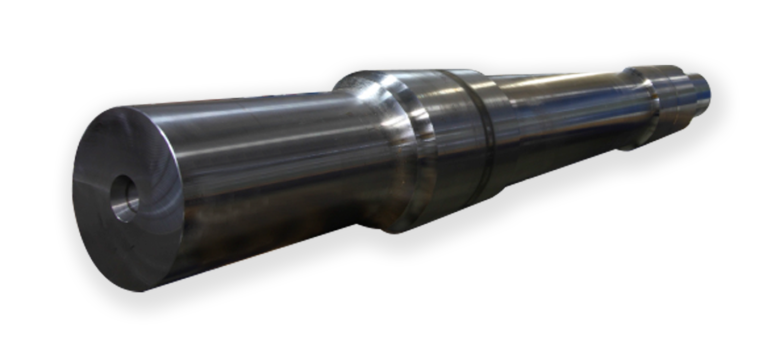

Our axles are engineered to withstand the increased stress from the heavier freight loads of today. With precision engineering, exacting tolerances, and rigorous manufacturing processes, these axles ensure superior reliability and performance, crucial for the heavy haul market. They are produced with meticulous attention to detail, from cast ingot to finished product, ensuring no margin for error.

Founded in 1949, Brenco® Bearings has been a pioneer in manufacturing tapered roller bearings for railroad freight cars. Known for their durability and performance, these bearings are designed to meet the exacting demands of the heavy haul market, ensuring long distances with minimal maintenance.

Choose from a wide range of AAR-approved braking equipment engineered for optimal performance under the rigorous conditions of heavy haul service. These brake systems are designed for reliability, long service life, and minimal maintenance, ensuring safe and efficient operation over long distances.

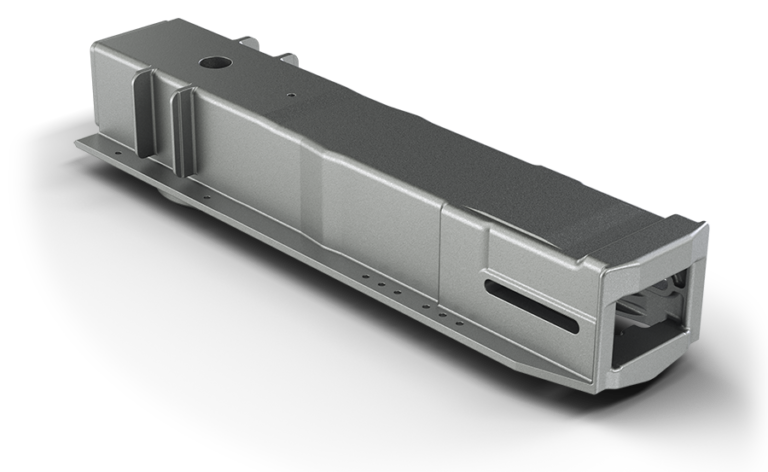

The Low Profile Center Plate is designed for reduced weight and increased longevity. With improvements in key areas, it offers lighter weight, increased strength, and reduced installation costs. Center Bowl Liners prevent wear on centre plate and centre bowl surfaces, ensuring precision fit and enhanced durability.

Our coil springs are manufactured with excellent process control, ensuring consistency in dimensional, metallurgical, and functional properties. Custom-designed for demanding applications, these springs undergo shot peening and heat-treating processes to ensure durability and performance.

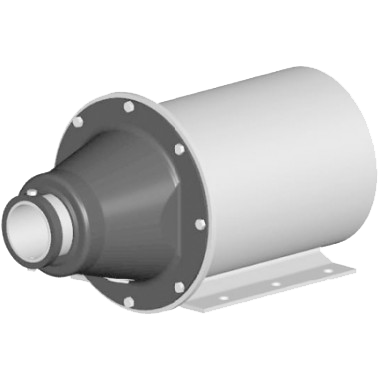

We offer a comprehensive range of AAR-approved railcar connection solutions designed for safety, reliability, and performance. Our product lineup includes durable, Transnet-approved couplers, articulated connectors, and robust knuckles engineered to reduce impact stress and ensure the integrity of railcar connections. For enhanced efficiency, our flame-hardened drawbars deliver up to 60% slack reduction and significant weight savings, while our hydraulic cushioning units, featuring industry-standard 10-inch shock absorbers, provide exceptional protection for fragile and high-value cargo. These components are designed to meet the diverse demands of the railroad industry, ensuring optimal performance across various applications.

Designed to protect fragile cargo, our cushioning units include shock absorbers and a full line of AAR-approved hydraulic devices. These units are engineered to reduce impact stress, ensuring safe and efficient transportation of high-value items and minimising damage.

Our draft sills and draft gears are designed to provide the toughest protection against the stresses of railcar operation. These components are precision-engineered to reduce impact stress, extend the service life of railcars, and ensure reliable performance under demanding conditions.

Friction damping systems are designed to improve ride quality and truck performance. With a long history of innovation, these systems ensure longer life cycles for railcar components by providing optimal solutions for both performance and longevity.

The Hollube® and Hollamax™ Wear Prevention Products, made from advanced plastics, significantly reduce wear and outlast steel. These products lower replacement costs and improve the longevity of railcar components, providing cost-effective wear solutions.

Our pellet car components meet rigorous EPA regulations and set new standards for reliability and performance. These components effectively control pellet movement, minimising shattering and contamination, and ensuring efficient and safe transport of plastic pellets.

We supply a wide range of high-quality wheels that set the standard for design, manufacturing innovation, and reliability. Backed by Transnet’s unconditional approval, our advanced wheel technology ensures greater strength at higher temperatures, resulting in fewer wheel-set removals, extended wheel life, and a proven track record of performance.

Wheel Engineering Highlights:

Our products are meticulously designed and tested to meet the diverse demands of the rail, industrial, and engineering sectors, ensuring exceptional performance and reliability in every environment.